NCCM™ (3M) Mill Rolls Availability & Charactoristics

| Color | pH Range | Density | Typical Applications | |||

| 3 | 5 | 7 | 9 | |||

| Yellow | 2-10 | X | X | X | X | *Wringing *Ironing *Oil appplication *Bridle *Tensioning *Steering rolls *Deflector *Snubber *De-oiling *Metering |

| Mottled green and black | 0-14 | X | X | *Wringing feed rolls in a chemical environmont with no petroleum | ||

| Mottled brown and black | 0-14 | X | X | *Wringing applicator for chemtreat solutions | ||

| Mottled green and yellow | 0-14 | X | X | *Wringing *Metering *Sunbber *Steering rolls | ||

| Blue | 2-10 | NA | *Bridle * Snubber *Table rolls | |||

Compressible NCCM™ Mill Rolls

Tight Contact for Consistent Wringing, Oiling, and De-oiling

Wringing

NCCM™ Mill Rolls are slightly compressible with a porous opensurface. With the compressible, sponge-like characteristic,the rolls conform to the smallest variations in gauge thickness to maintain consistent tight contact across the strip. This tight contact helps assure exceptionally uniform wringing. Strips emerge drier from the rinse tank, and in some cases, users have found up to a 95 percent reduction in solution “carry through” compared with conventional rubber rolls. And the porous surface absorbs fluid to greatly reduce the chance of hydroplaning which can cause slippage.

Oiling and De-oiling

With tight contact, 3M Mill Rolls meter and apply lubricantsconsistently and uniformly. And operators can remove excessprotectant oils on incoming metal strip. This “de-oiling”helps reduce costs and improve capabilities in the causticcleaner. For more information on oiling and de-oiling, pleaserefer to the relevant 3M application notes .

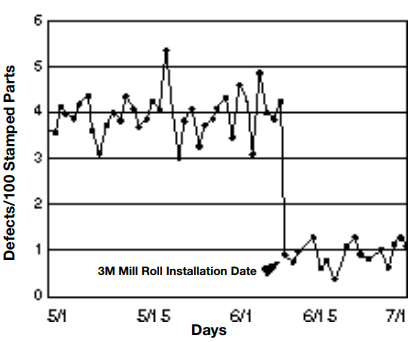

Defects reduced

The results of 3M Mill Rolls replacing rubber rolls in an automotive stamping operation are shown below. With the more effective wringing action of the 3M rolls, defects were reduced from four per hundred stampings to approximately one per hundred.

Broad Operational Pressure Range

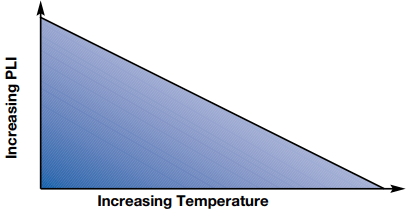

3M Mill Rolls can be used within a wide range of pressures and temperatures and still provide excellent wringing. Wringing has been evaluated under a wide range of operating pressures. Nip pressure as measured in pounds/linear inch of roll width (PLI) is the key parameter.

Neutral, RK Rolls

Maximum continuous operating temperature for 3M Neutral and RK rolls is 285°F (141°C). 3M Neutral roll maximum operating pressure depends on roll density. RK roll maximum PLI is 100.

C, CX, D Rolls

Types C, CX and D maximum operating pressures are dependent on operating temperatures. For these rolls there is an inverse relationship between temperature and pressure as indicated in the graph above. Due to the variations in the three types, please refer to the relevant 3M application notes.

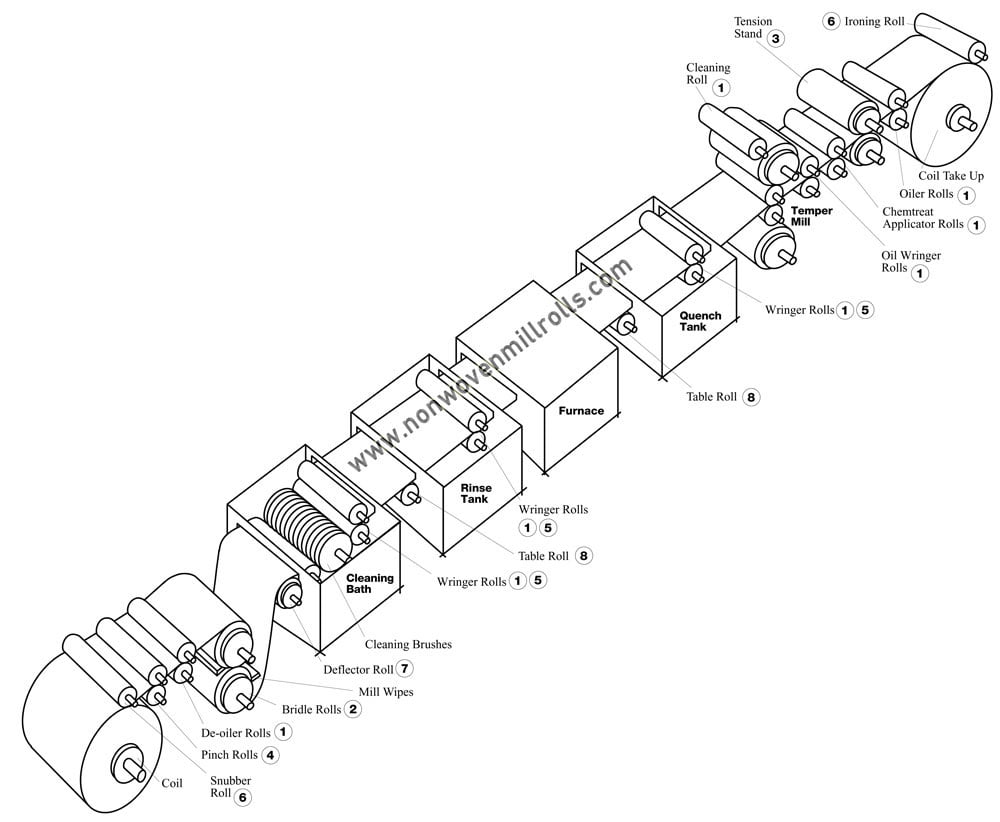

| Application | NCCM Mill Roll | |

| 1. Wringer roll Oiler roll Oil wringer roll Cleaning roll De-oiler roll | Acid 0-2 pH Neutral 2-10 pH Caustic 10-14 pH Chemtreat Oiler/de-oiler | Type C, CX Neutral Type C, CX, D Type CX Neutral |

| 2. Bridle roll | Neutral , RK | |

| 3. Tension stand roll | Neutral | |

| 4. Pinch roll Feed roll | Environment dependent | All |

| 5. Steering roll | Environment dependent | All |

| 6. Snubber roll Ironing roll | Neutral , RK | |

| 7. Deflector roll | Neutral , RK | |

| 8. Table roll Carrier roll Swing Arm roll | Environment dependent | All |

| 9. Measuring roll | Environment dependent | All |