By using the m ethod of horizontal continuous casting and high-precisin cold-rolled, high-perfomance tin phosphorus bonxe C5210 copper is studied. The difficulty that 400 mm wide high perfomance tin phosphorus bronze C5210 copper cannot be rolled is solved by using large processing rate, 3M non-woven mill rolls and tension leveling and transfoming the 14-high roller mill of the stainless steel industry. The tensile strengh in SH state can be up to more than 730MP, the elongation can be up to over 12% and the thickness accuracy can be about 0.002mm, which meet the requirements of customer for high-perfomance and high elasticity copper.

With the development of industrial production, the components of electronics, telecommunications, electrical appliances and other products are becoming more and more miniaturized and dense, requiring copper foil strips with thinner thickness and higher mechanical properties. Since electrolytic copper foil is electroplated, the crystalline state of its copper particles is vertical needle-like, and the needle-like structure is prone to breakage during dynamic bending, while the copper particles of rolled copper foil have a horizontal axis-like structure, which can be bent and folded many times. The ductility, bending resistance and surface smoothness of the foil are better than those of electrolytic copper foil.

This project adopts the international advanced production technology to study the tin phosphor bronze C5210 copper foil, and the developed product belongs to the rolled high-performance alloy copper foil is the basic material of the electronics industry.

1 Research status of domestic copper foil

The copper foil strip can be produced by electrolysis and rolling. At present, the ultra-thin double-sided bright high-performance electrolytic copper foil and its preparation method have been successfully developed in China. The thickness can be no more than 84m, the roughness is no more than Q.25Hm, and the elongation is greater than 5%; due to different product requirements, the high-performance tin phosphor bronze C5210 copper foil material must be produced by rolling, which is limited by equipment, technology and other factors , Only a few domestic manufacturers can produce copper foil, which is rolled by domestic rolling mills, and some strips appear wavy and broken, and the oil removal effect during the rolling process is poor, and the rolling width is less than 305mm, which cannot be fully satisfied. Customer requirements.

2 Main technical indicators of the product of this project

With reference to the copper alloy strip standards of the Japanese JIS standard and the American ASIM standard, combined with the market requirements, the enterprise standard is compiled. The main technical indicators are shown in Table 1 and Table 2.

| Grade | Cu | Pb | Fe | Sn | Zn | Mn | Ni | P | Cu+Sn+P |

| C5210 | ≤0.02 | 0.10 | 7.0-9.0 | ≤0.20 | 0.03-0.35 | ≥99.5 |

| Grade | Status | Thickness, mm | Tensile Strength, MPa | Elongation, % | Vickers Hardness, HV |

| C5210 (QSn8-0.3) | SH | 0.05-0.15 | 730-830 | ≥10 | 230-250 |

3 Product research and technical solutions

3.1 Determination of product grade, specification and state

The product grade is determined as tin phosphor bronze C5210 (QSn8-Q3); the product state is EH and SH; the thickness is 0.07mm, 0.075mm, 0.08mm; the width is 305~ 400mm.

3.2 Determination of product process route

The production process of “horizontal continuous casting billet supply-cold rolling-annealing-finishing” is used to study the tin phosphor bronze C5210 copper foil.

4 Product research process analysis

4.1 Improve the product rolling process to solve the problems of copper foil easily broken and difficult to control the shape of the plate.

This project renovated the fourteen-high finishing mill in the stainless steel industry, and applied it to the copper processing industry for the first time. The thickness control system of the rolling mill was changed from the original one. The Y-ray was changed to a contact thickness gauge produced by Vollmer, Germany.

In order to avoid insufficient measurement accuracy due to changes in composition, the supporting electrical transmission control, hydraulic pressure, lubrication and other aspects of the system were transformed. At the same time, the existing dual-flow 440mm tin phosphor bronze production line was studied, and the final trial product width can reach 400nm.

The characteristics of rolling high-strength alloy copper foil are that the absolute reduction is small, the relative reduction is large, the roll is in a negative roll gap, the rolling force is large, and the rolling pressure limit alarm often occurs. The copper foil rolling procedure selects 3~4 passes and uses a small pass processing rate. The first pass processing rate does not exceed 259, and the remaining passes are gradually reduced according to 2~4 processing rates. The distribution method. The front tension is less than the back tension setting, and the former is 10~25kN less than the latter. This process has stable rolling and can solve the problem of strip interruption in the rolling process.

The fourteen-high rolling mill is a multi-high rolling mill with multi-means to adjust the shape condition. When the high-strength copper alloy foil is rolled, it will lead to poor shape due to slight uneven deformation. In view of this situation, the fourteen-high The shape adjustment method of the rolling mill is to determine the best shape control parameters by using the fourteen-high mill pull-out roll and roll shape:

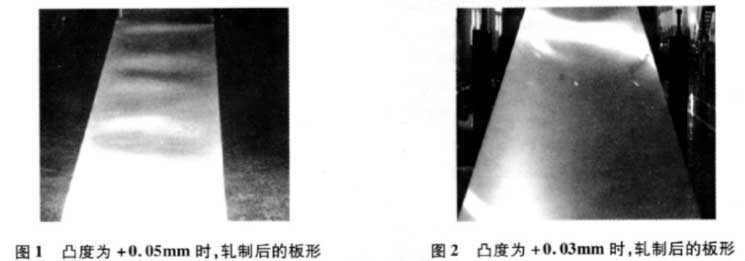

(1) Analyze the force of the second intermediate roll when rolling copper alloy foil, and test the influence of the rolls with convex roll profiles of +005mm and +Q03mm on the strip shape during rolling. In the comparison test, the crown of the convex roll was finally determined to be +003mm, and the generation of intermediate waves during rolling was reduced by groping the roll shape of the convex roll.

Figures 1 and 2 are pictures of the shape of the flat rolled with different crowns.

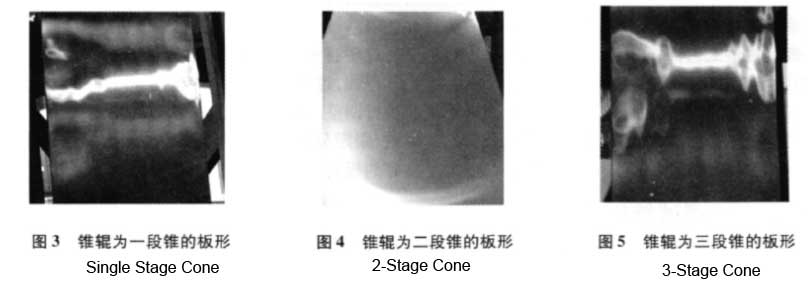

(2) Since the fourteen-high mill is applied to the production of stainless steel strips, the product with a width of 420nm is rolled with a tapered roll shape: the taper length is 120mm, and the taper is Q36mm. This tapered roll shape is used in rolling copper. Double-sided waves are prone to occur when the alloy foil is used.

After the force analysis of the entire roller system, three schemes of one-stage cone, two-stage cone and three-stage cone were tested. The result is that the two-stage cone roll type is ideal, the cone length is 230mm, and the edge cone length is 170nm, and the taper is 0. 36mm; middle taper length is 60mm, taper is Q04mm.

By changing the roller system, the influence of the double-sided waves on the strip shape quality is eliminated.

Fig. 3. Fig. 4 and Fig. 5 are pictures of rolling plate shapes using three types of tapered rolls.

4.2 The application of 3M rolls on the domestic 14-high rolling mill solves the problem of degreasing in foil strip rolling.

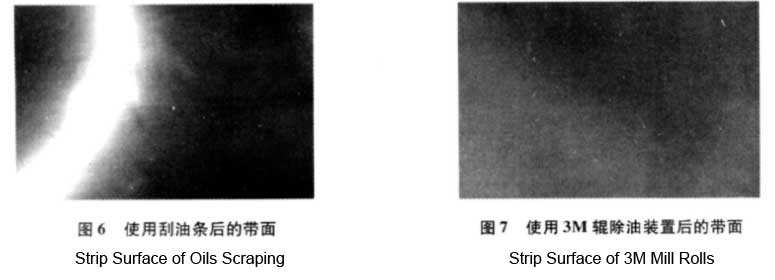

At present, the main methods of degreasing include squeezing and scraping.

The 14-roll mill chooses the method of oil scraping in the production of stainless steel. The oil scraper is made of plastic material, and the oil removal effect is good. However, when the oil removal device is used for rolling copper foil, because the copper strip is softer than the stainless steel material, after a period of use, the rolled copper powder is easy to accumulate on the side of the oil scraper, causing scratches on the surface of the strip, which seriously affects the surface quality of the strip, so the oil scraping device cannot be used.

If the roller squeezing method is selected, the squeezing effect cannot be achieved because the material is too thin. For this reason, the 3M squeezing roller is studied and transformed, and it is applied to the 14-roll mill to solve the problem of strip surface degreasing.

Figure 6. Figure 7 shows the pictures of the oil scraper and the 3M roller degreasing device when rolling the foil.

4.3 During the rolling process of the finished product, the large processing rate is used to make the product obtain high strength performance indicators above 730MPa.

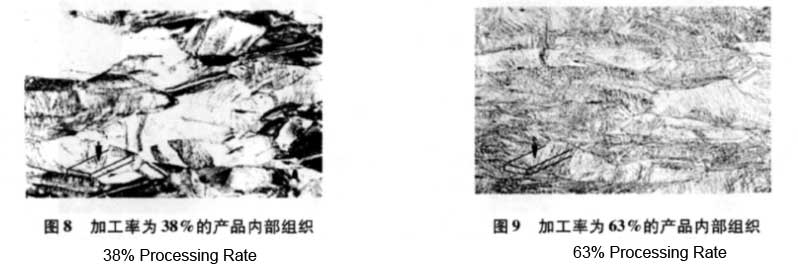

The metal material undergoes plastic deformation during the rolling process, and the phenomenon of work hardening occurs, and the mechanical properties of the material are significantly improved.

In the fully recrystallized state of tin phosphor bronze, with the increase of the processing rate, the performance of the material is also getting higher and higher. Therefore, the performance index of the product is controlled by exploring the corresponding processing rate. The tensile strength is above 730MPa, and the The total processing rate is above 50%, and the highest can reach 63%. Of course, the performance of the recrystallized state (also known as the bottom) has a certain influence on the performance of the final product.

Figure 8. Figure 9 shows the microstructure pictures of rolled products with low processing rate and high processing rate respectively.

4.4 Research product bottom annealing process

To ensure high-strength performance indicators, the bottom annealing can be used in two ways: a bell annealing furnace and an unfolding air cushion furnace. For thin strips with a thickness of less than 0.2mm, both annealing methods are insufficient.

Since the bell-type annealing furnace is used for coil annealing, there is a serious bond between the copper strips, and the surface quality cannot be guaranteed.

When the thin strip is annealed in an air cushion furnace, there are two main problems. One is that the strip is thin and soft, and the strip is easy to break in the furnace area; The other one is that the running speed is limited, and after the annealing, the strip is too soft, the finished product performance is too low to meet the requirements.

Based on the above two points, air cushion furnace annealing is adopted for the bottom reserve, and the tension and wind pressure of the furnace area of different specifications of the bottom reserve material are mainly explored to ensure that the copper strip can operate normally and continuously.

Since the performance of the bottom material affects the performance of the finished product, it is necessary to adjust the annealing temperature and annealing speed, and adjust the annealing temperature at the fastest speed to ensure that the bottom is annealed normally and ensure that the performance of the finished product meets the high performance requirements.

4.5 Determine the tension leveling process to ensure the straightening effect

The stretch-bending leveler is mainly carried out by means of straightening tension and segmental adjustment of the support rollers. Since the thickness of the copper foil is less than Q lmm, which is already less than the minimum thickness Qlmm of the stretch-bending leveler, it is easy to produce over-straightening and strip breakage in the process. , poor straightening effect and a series of problems.

In order to complete the straightening treatment of copper foil, the straightening process must be adjusted. It is tension control. The given tension must meet the requirements of straightening, and it is necessary to prevent the belt from being broken due to excessive tension; the second is to adjust the appropriate roll gap. Limit the maximum value of the segmental adjustment pressure to prevent overcorrection.

The straightening process is determined through continuous experiments to ensure the straightening effect and obtain a good plate shape.

5 Product Research Test Results

The test results of the product sent to the testing center of Chinalco Luoyang Copper Co., Ltd. are shown in Table 3 and Table 4.

The degreasing of the strip surface of the rolling mill is a worldwide problem. To choose a good degreasing method, it must have a good degreasing effect. , without causing damage to the surface of the material.

| Grade | Cu | Pb | Fe | Sn | Zn | Mn | Ni | P | Cu+Sn+P |

| C5210 | ≤0.02 | 0.10 | 7.0-9.0 | ≤0.20 | 0.03-0.35 | ≥99.5 |

| Grade | Status | Thickness, mm | Tensile Strength, MPa | Elongation, % | Vickers Hardness, HV |

| C5210 (QSn8-0.3) | SH | 0.05-0.15 | 730-830 | ≥10 | 230-250 |

6 Conclusion

(1) This project researches and transforms the fourteen-high rolling mill used in the stainless steel industry, applies the 3M roller degreasing device, carries out technological innovation and improvement of the process, and develops a wide (400mm) high-performance tin-phosphor bronze C5210 copper foil. It solves the problem that 400mm wide high-performance tin-phosphor bronze C5210 foil cannot be produced by rolling in China.

(2) Research on the bottom-retaining annealing process solves the problem that the bottom-retaining annealing process for thin strip products is difficult to achieve. By adopting process methods such as large processing rate and stretch-bending straightening, the performance indicators of good shape and high strength are obtained.

(3) The tensile strength of the product in SH state reaches more than 730M Pa, the thickness accuracy is 0 002nm, and the technical indicators have reached the international advanced level. The product has been recognized in the market and can replace imported products.